Harley Davidson Exhaust Bolt Torque

Exhaust Torque specs.

Harley davidson exhaust bolt torque. Fastener Size - Torque ft. Then remove the rear exhaust pipe mounting bolts. You really should get the manual specific to your model.

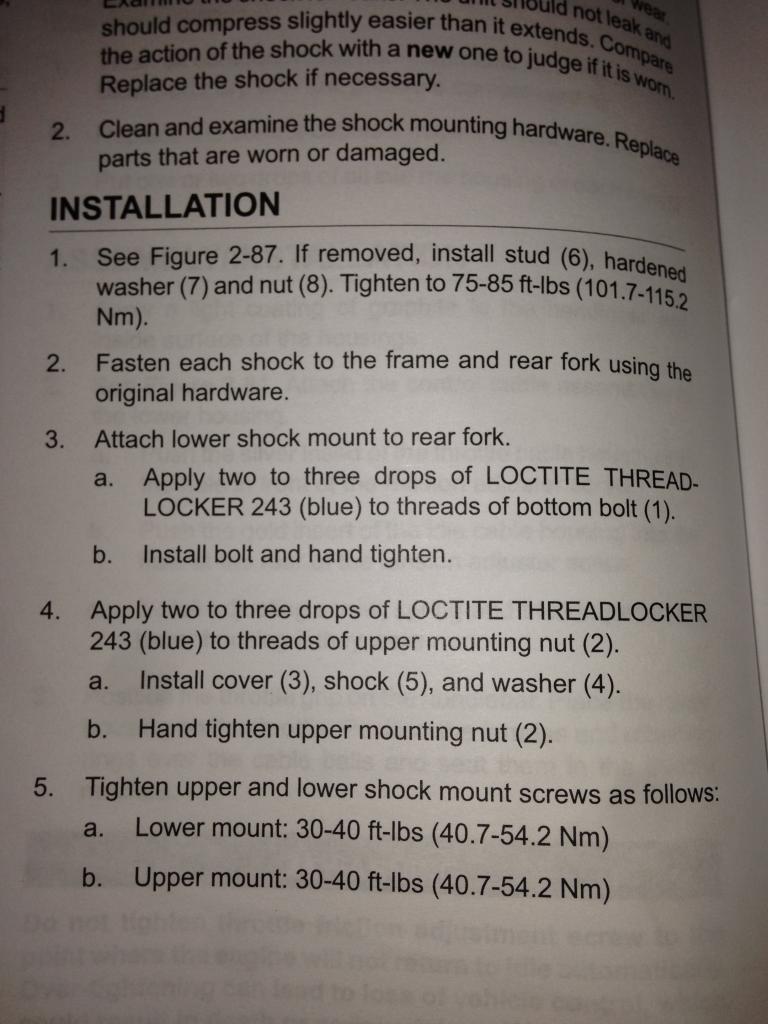

4 Tighten each bolt to 38-42 foot pounds of torque. The torque values I found for that size thread gives 8 ftlbs for a steel to steel interface. Tighten the top nut of the front cylinder head exhaust flange to 9-18 in-lbs 1-2 Nm then tighten the bottom nut to 100-120 in-lbs 113-136 Nm final tighten the top nut to 100-120 in-lbs 113-136Nm then tighten the bottom nut of the rear cylinder head exhaust flange to 9-18.

Route the oxygen sensor wiring back to their respective plugs and secure with wire ties as necessary. Locate the flangeor flat rimon both the torque cones and the exhaust. This might be a bit high but because it is a steel stud in an aluminum head it could serve as a guide to a maximum limit.

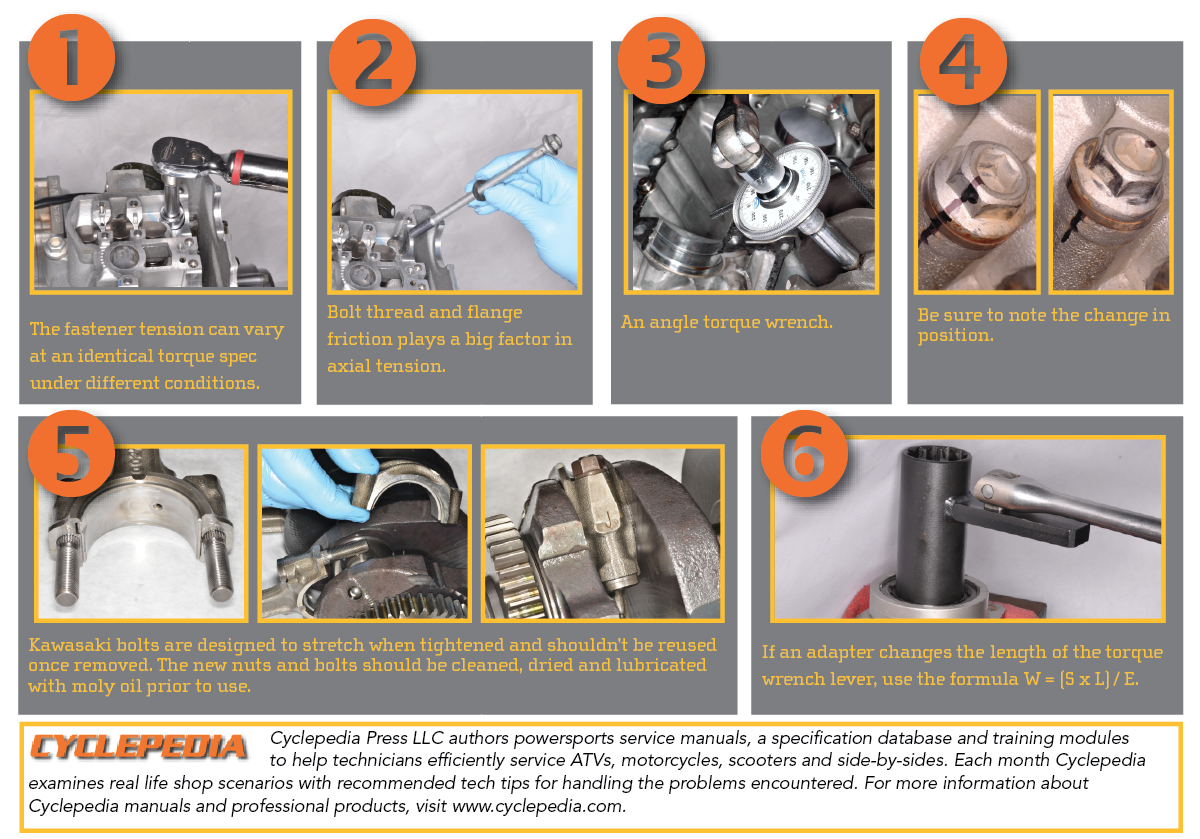

516585 Nm 3843 ft-lbs clamp bolt NOTICE Wipe all fingerprints off of exhaust system components after installation and before starting engine. Today Doc Harley explains the importance of checking the torque on your exhaust bracket boltsharleydavidson torque motorcycles. You get a feel for the torque by taking a torque wrench and turning to the specified torque on something else to get the feel for the specified torque.

If you are referring to the cylinder head exhaust flange --- tighten the top nut of the front head to 9-18 in-lbs then tighten the lower nut to 120 in-lbs finally tighten the top nut to 120 in-lbs. Discussion Starter 1 Mar 6 2008. I just use lock washers on my ex.

Just watched this video about checking the bolt torque for exhaust brackets for aftermarket exhaust. Ad Fast Free Shipping on Orders Over 40. Insert the small end of a torque cone into each of the two exhaust pipe openings until the flange on the cones comes against the flange on the exhaust pipes.